In-House Supplier +

Partner Auditing

We run our own in-house partner auditing program to personally visit suppliers in our network to ensure they’re meeting Bobbie’s standards for quality and food safety.

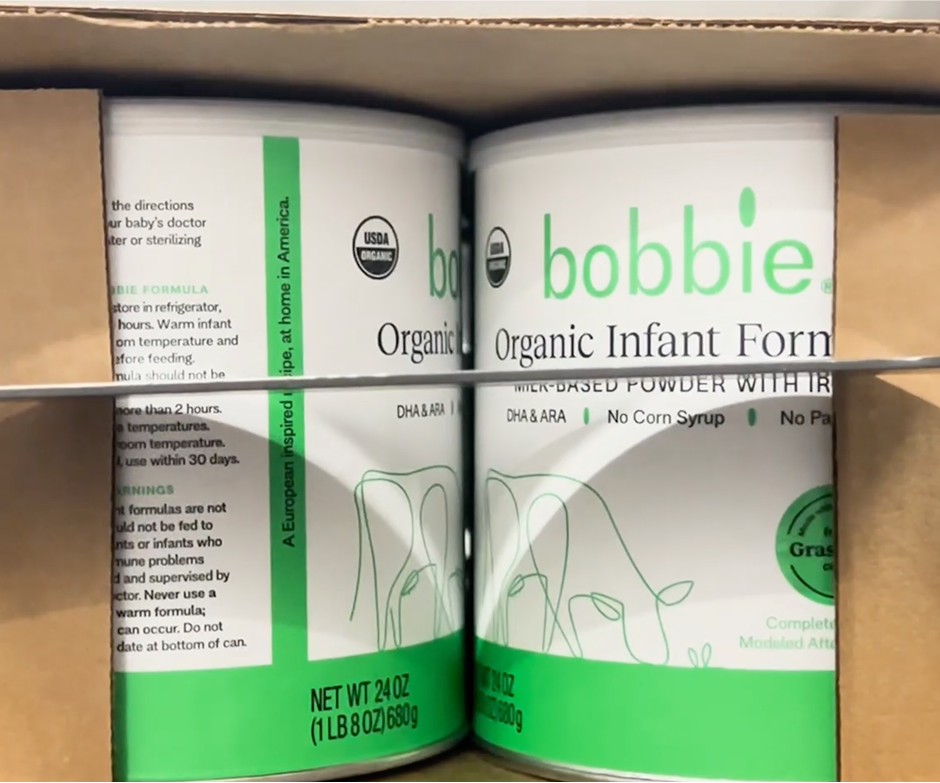

Precision Can Filling

We’ve invested in precision weighing and scale systems to ensure each can is filled consistently and evenly to National Institute of Standard and Technology specifications.

2,000 Quality Checks

We conduct 2,000 minimum quality checks so you can feel confident about what you pour into your baby’s bottle.

Microorganism Testing

Each individual batch of Bobbie is tested for pathogens including cronobacter and salmonella bacteria.

Cutting-edge quality +

safety protocols.

MANUFACTURING

We prioritize quality, trust, and safety every step of the way—from sourcing raw materials to canning and production. We take pride in our ability to produce Bobbie in-house at our Ohio facility, complemented by longstanding partnerships with trusted co-manufacturers known for their decades-long commitment to safety.

100% pure Bobbie.

Like, 2,000-quality- checkpoints-pure.

TESTING

Top-of-the-line quality & regulation by our in-house experts. By thoroughly testing our ingredients, batches, and shelved product, we ensure every ounce meets our stringent purity standards. Before canning, each batch is tested for contaminants, microorganisms, or naturally occurring heavy metal residue—as well as ensuring the vitamin and mineral levels match our recipe. Not a single batch leaves the facility until it goes through all 2,000 quality checkpoints.

What’s outside

matters, too.

DISTRIBUTION

From the moment Bobbie departs our facilities, our distribution partners are on formula duty. Our distribution and delivery partners are vetted against our quality standards and FDA-regulated food transportation laws. Everything from facility conditions, sanitation, and temperature controls, to security procedures and employee training protocols are subject to 3rd party audits and review cycles.

Trace your Product

Enter the lot code number (case-sensitive) printed on the bottom of each can of Bobbie to trace its history, packaging details, expiration date, and more.